Product List

- Paper Cup Machine

- MB-C12H High Speed Paper Cup Machine

- MB-C12 Medium Speed Paper Cup Machine

- MB-A12 Single PE Coated Paper Cup Machine

- MB-S12 Double PE Coated Paper Cup Machine

- MB-S16 Ultrasonic Double PE Coated Paper Cup Machine

- MB-S22 Ultrasonic Double Side PE Paper Cup Machine

- MB-12/22 PLC Controlled High Speed Paper Cup Machine

- YK-12 Cup Top Flatten Machine

- Paper Bowl Machine

- MB-D35 Automatic Single PE Coated Paper Bowl Machine

- MB-S35 Ultrasonic Double PE Coated Paper Bowl Machine

- MB-ZT-200 Automatic Paper Bucket Forming Machine

- MB-400 Medium Speed Paper Plate Machine

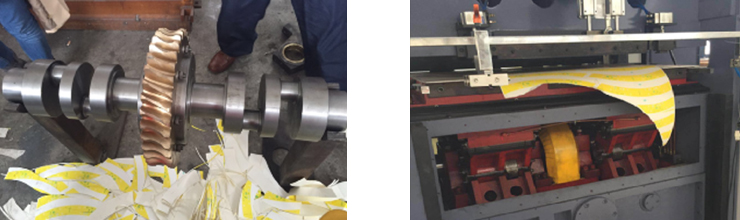

- Die Cutting Machine

- MB-980 Automatic Paper Roll Die Cutting Machine

- J-DC930 Automatic Paper Roll Die Cutting Machine

- MB-CQ-850 Automatic Punching Die Cutting Machine

- J-DC750 Automatic Platen Die Cutting Machine

- MB-800 Creasing Die Cutting Machine

- Cup Lid Machine

- MB-350 Plastic Cup Lid Forming Machine

- MB-420 PLC Controlled Automatic Cup Lid Forming Machine

- Automatic Paper Lid Forming Machine

- Flexo Printing Machine

- RB-850 4-6 Color Flexo Paper Cup Printing Machine

- RB-650 4-6 Color Flexo Printing Machine

- Other Paper Product Machines

- MB-800A Carton Erecting Machine

- MB-T09 Callipo Tube Forming Machine

- ZWT-35 Automatic Paper Cup/Bowl Outer Sleeve Forming Machine

- ZKT-09 Double Wall Paper Cup/Bowl Machine

- Automatic Paper Lunch Box Machine

English

English Español

Español Русский

Русский

Coffee Paper Cup Making Machine

Coffee Paper Cup Making Machine Cold Drinks Paper Cup Making Machine

Cold Drinks Paper Cup Making Machine Disposable Paper Cup Making Machine

Disposable Paper Cup Making Machine Drinking Cups Making Machine for Hot

Drinking Cups Making Machine for Hot Juice and Shake Paper Cup Making Machine

Juice and Shake Paper Cup Making Machine Take Away Paper Juice Cup Making Machine

Take Away Paper Juice Cup Making Machine Tea Paper Cup Making Machine

Tea Paper Cup Making Machine Water Paper Cup Making Machine

Water Paper Cup Making Machine